Food & Beverage

Ensuring Traceability and Compliance: Your Guide to Mixed Pallet Management

| Kargo | 9 min

What You Need to Know

Kargo data reveals that 8% of all perishable pallets have either multiple expiration dates or multiple lot codes. While this may not seem like a huge number, handling these kinds of pallets, also known as mixed pallets, can be challenging and have significant implications.

Effective management of pallets with multiple expiration dates or multiple lot codes is critical to ensuring compliance with stringent food safety regulations and enhancing the traceability of food products. The stakes are high: mishandling can lead to serious regulatory repercussions, costly recalls, and the erosion of consumer trust.

Here, we’ll look at the challenges in managing pallets with multiple expiration dates and lot codes, as well as the latest strategies for enhancing compliance and traceability.

Understanding Compliance and Traceability

In the food logistics, compliance and traceability are paramount for ensuring product safety and adhering to regulatory standards. These concepts become especially critical when dealing with pallets that contain products with varying expiration dates and lot codes.

Compliance:

Specific regulations that impact mixed pallets often revolve around the storage and handling of perishable goods. For example, the Food Safety Modernization Act (FSMA) emphasizes preventive controls and requires food facilities to implement a food safety plan that includes hazard analysis and risk-based preventive controls. These regulations extend to ensuring that products on mixed pallets are stored in a manner that prevents cross-contamination and that products are rotated based on their expiration dates to minimize the risk of selling or using expired goods.

Traceability:

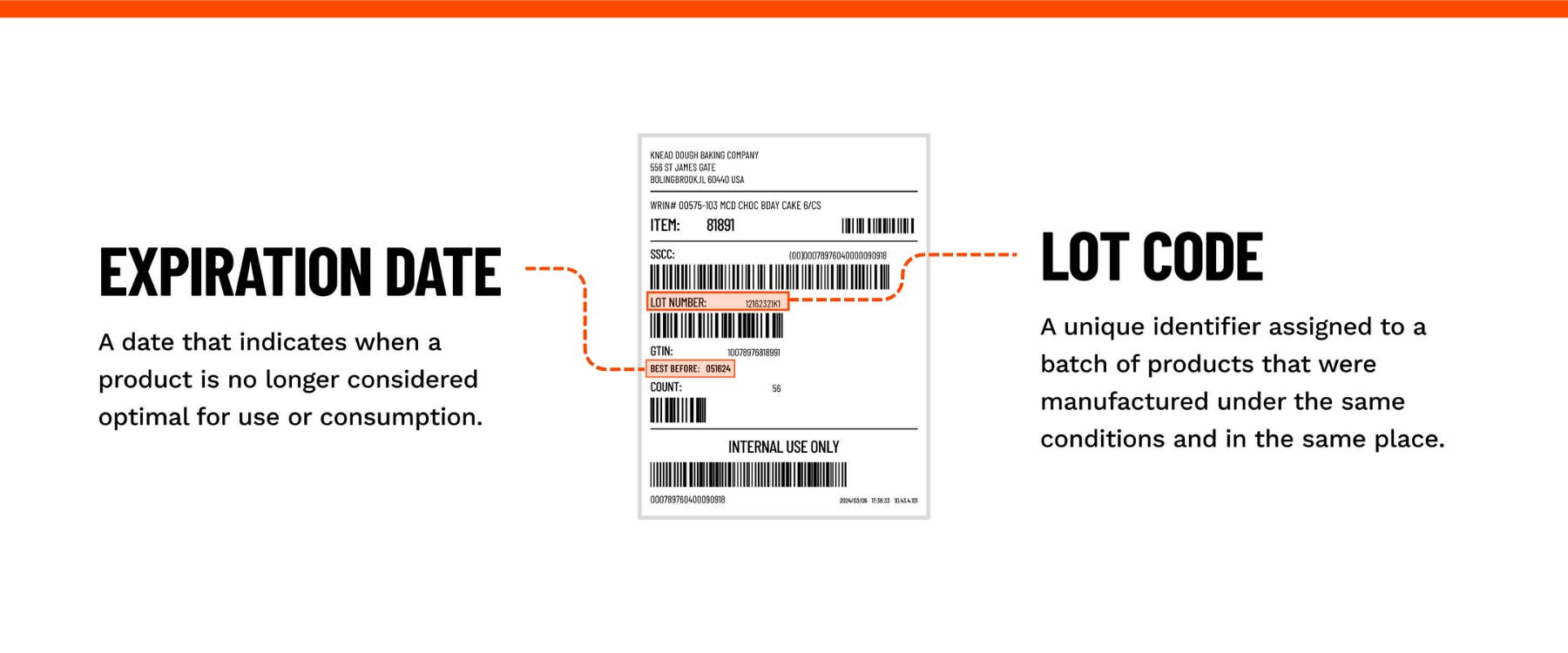

Lot codes and expiration dates are crucial elements in the traceability of food products. Regulations, such as those implemented by the FDA’s Food Traceability Rule, which focuses on enhancing recordkeeping for certain high-risk foods, underscore the need for detailed tracking information. This includes maintaining records of lot codes and expiration dates at every point in the supply chain, from production to distribution. In the event of a food safety issue, having this information readily available allows for swift action to be taken, such as conducting targeted recalls that minimize consumer exposure to potential hazards.

For warehouses managing mixed pallets, the challenge lies in maintaining an accurate, accessible record of these data points. Compliance ensures that products are stored and handled according to safety standards, while traceability enables the warehouse to provide a detailed account of a product's journey and condition at any given time. Together, these elements form the backbone of a robust food safety strategy, ensuring that warehouses not only meet regulatory requirements but also play a critical role in protecting public health.

Challenges in Managing Pallets with Multiple Expiration Dates or Lot Codes

Warehouses face distinct challenges when managing pallets with products that have various expiration dates and lot codes. Each challenge poses specific risks that can affect the safety and efficiency of the supply chain.

Complex Inventory Rotation

Organizing and selecting products based on the closest expiration date while considering lot codes requires precise tracking and can complicate product rotation.

Failing to adhere to the First Expired, First Out (FEFO) or First In, First Out (FIFO) inventory management principles due to mixed lot codes and expiration dates increases the risk of selling or using outdated products.

Example: If a pallet contains two batches of yogurt, one expiring in a week and another in a month, staff need to ensure the batch with the impending expiration date is shipped or used first, regardless of the lot codes. Mismanagement here could lead to the fresher batch being used first, leaving the older one to expire and result in waste.

Inventory Management Intricacies

Warehouses must manage inventory data for each lot code and expiration date, a process that becomes more complex with mixed-lot pallets, demanding robust inventory management systems.

Inaccurate inventory tracking can lead to overstocking or stock shortages, impacting supply chain reliability and financial outcomes.

Example: A warehouse receiving a pallet with two lot codes of canned tomatoes, each with different expiration dates, must record these details accurately. Failing to do so could result in an inaccurate stock count, leading to potential overordering of one lot or underordering of another, disrupting inventory balance.

Enhanced Risk of Human Error

Manual processes for recording and verifying multiple lot codes and expiration dates during shipping and receiving is prone to errors, which can lead to misshipment or improper storage.

Example: Upon receipt, a warehouse worker might only record the one expiration date for a pallet with multiple expiration dates. This error could lead to the pallet not being broken down and product being stored longer than recommended, potentially risking violating compliance regulations if shipped.

Recall Procedure Complications

In the event of a product recall, identifying and isolating specific items based on lot codes and expiration dates from mixed pallets can be challenging and time-consuming.

This can potentially slow down the recall process and increase health risks.

Example: If a particular lot code of peanut butter is recalled due to contamination, but the pallets are mixed, warehouse staff must sift through potentially hundreds of units to find and remove the affected ones, delaying the recall process and increasing the risk of contaminated products reaching consumers.

Compliance and Safety Concerns

Warehouses must comply with regulations that dictate how different products, based on their lot codes and expiration dates, should be stored and handled to ensure safety.

Non-compliance with storage and distribution regulations specific to certain lot codes and expiration dates can lead to legal penalties and harm the brand's reputation.

Example: Certain pharmaceutical products might have storage requirements that vary by lot, based on production conditions. If a warehouse mixes these lots on the same pallet without adhering to the strictest storage conditions, it could compromise the efficacy of the medication, leading to serious health risks for end-users.

ASNs and Liability for 3PLs

Third-party logistics providers (3PLs) are increasingly held accountable for ensuring the accuracy and integrity of the data associated with the products they handle. This includes verifying that the lot codes and expiration dates on the products match those listed in the Advanced Shipping Notices (ASN).

If a 3PL fails to identify discrepancies between the ASN and the actual shipment, or mixed pallets that a shipper did not denote, they risk reporting, storing and distributing products based on incorrect information. This can have serious implications for food safety and regulatory compliance.

Example: A 3PL fails to notice that a case of chocolate milk has a shorter expiration date than the rest of the cases on the pallet, leading to the distribution of nearly expired milk. When consumers fall ill, an investigation traces the issue back to the 3PL's oversight. This lapse results in legal penalties, a costly recall, and reputational damage for the 3PL, highlighting the critical need for 3PLs to accurately identify mixed pallets and verify ASN details to prevent health risks and ensure compliance.

To mitigate these risks, warehouses must employ advanced tracking and management systems, provide thorough staff training, and implement effective quality control measures. Such steps are crucial to handle the complexities of managing multiple expiration dates and lot codes, ensuring the safety and efficiency of the supply chain.

Strategies for Enhancing Compliance and Traceability

To effectively manage the challenges associated with multiple expiration dates and lot codes in warehouses, implementing robust strategies is essential. Here are some key approaches to enhance compliance and traceability:

Automate Scanning with Computer Vision

Using computer vision technology allows for instant data capture of lot codes and expiration dates at the loading dock and ensures complete data accuracy. Cutting edge systems like Kargo integrate with your existing inventory management systems to provide real-time data and streamline inventory tracking.

Benefits: Increased data accuracy, real-time inventory updates, and streamlined warehouse operations.

Develop Clear Segregation Protocols

Establishing clear rules for segregating products based on expiration dates and lot codes helps maintain order and prevents mix-ups. This might include physical barriers, designated areas, or special labeling.

Technologies like Kargo flag pallets with multiple expiration dates and lot codes as soon as they pass through the loading dock, making it easy to identify them and implement segregation protocols.

Benefits: Improved product rotation, reduced risk of contamination or error, and enhanced traceability.

Enhance Training Programs

Ongoing training programs ensure that staff are aware of the importance of managing multiple expiration dates and lot codes and are proficient in using technologies and following protocols designed for this purpose.

New technologies like Kargo are easy for workers to understand, while making their jobs easier by automating processes associated with mixed pallets and reducing human error.

Benefits: Well-trained staff contribute to fewer errors, more efficient operations, and a culture of compliance and safety in the warehouse.

Establish a Culture of Continuous Improvement

Encouraging feedback, adapting to new best practices, and regularly reviewing processes helps in refining strategies over time. This includes using data analytics to identify trends and areas for improvement.

Systems like Kargo that capture pallet level data, as well as track shift and supplier performance, make it easy to analyze trends and make data-driven decisions.

Benefits: Continuous improvement leads to progressively more efficient and compliant warehouse operations, adapting to changes in regulations or industry standards.

By addressing these strategies comprehensively, warehouses can significantly enhance their ability to manage products with multiple expiration dates and lot codes, leading to improved compliance, efficiency, and safety in their operations.

Conclusion

Managing pallets with multiple expiration dates and lot codes, presents a unique set of challenges for food suppliers and their 3PLs. However, by adopting technologies like computer vision for real-time data capture and establishing robust segregation protocols, warehouses can significantly reduce the risks associated with mixed pallets.

In an era where consumer safety and regulatory compliance are paramount, mastering the management of mixed pallets is not just an operational necessity but a competitive advantage.

Questions?

Connect With us

Ask us anything or drop your email to stay in touch