See Kargo in Action

Precision with every pallet

From automating processes to ensuring accuracy, Kargo turns everyday shipping and receiving challenges into opportunities for growth.

From automating processes to ensuring accuracy, Kargo turns everyday shipping and receiving challenges into opportunities for growth.

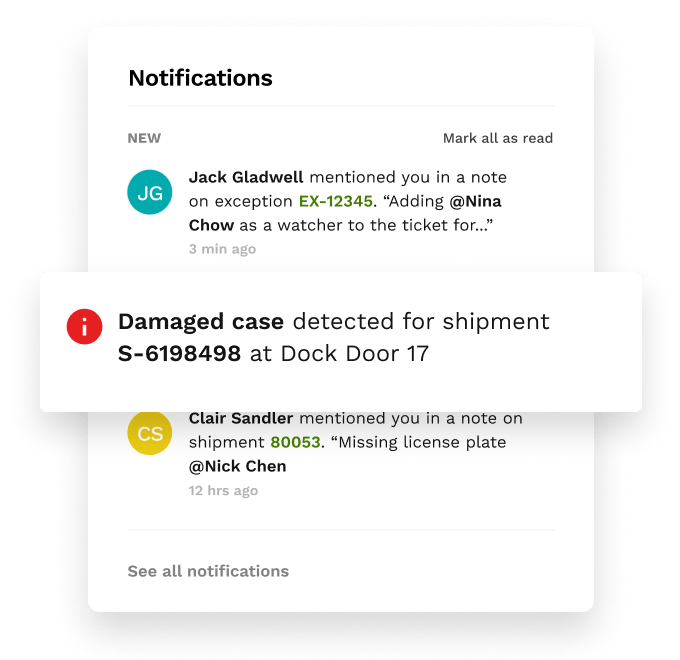

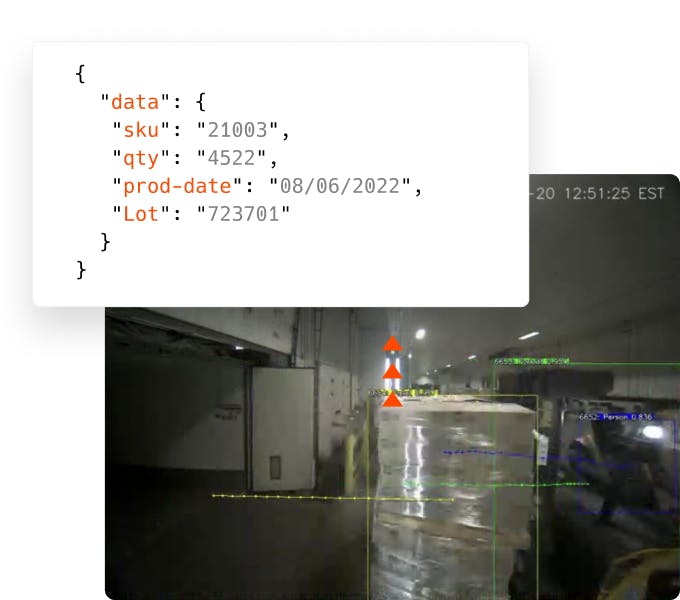

AUTOMATE THE WAY YOU SCAN

As the forklift drives through the dock door, Kargo automatically captures information from freight labels with complete accuracy.

- Eliminate Human Error: Automatically capture data from every label, keeping your inventory systems up-to-date and error-free.

- Increase Throughput: Enable fluid loading and unloading to streamline operations.

- Lower Operating Costs: Embrace Kargo’s scannerless workflow to reallocate labor.

The Breakdown

Kargo uses computer vision to gather information directly from labels as freight moves through the loading dock. No stopping or scanning required

In real-time, Kargo updates the Kargo Platform and existing management systems to ensure you’re always working with the latest data

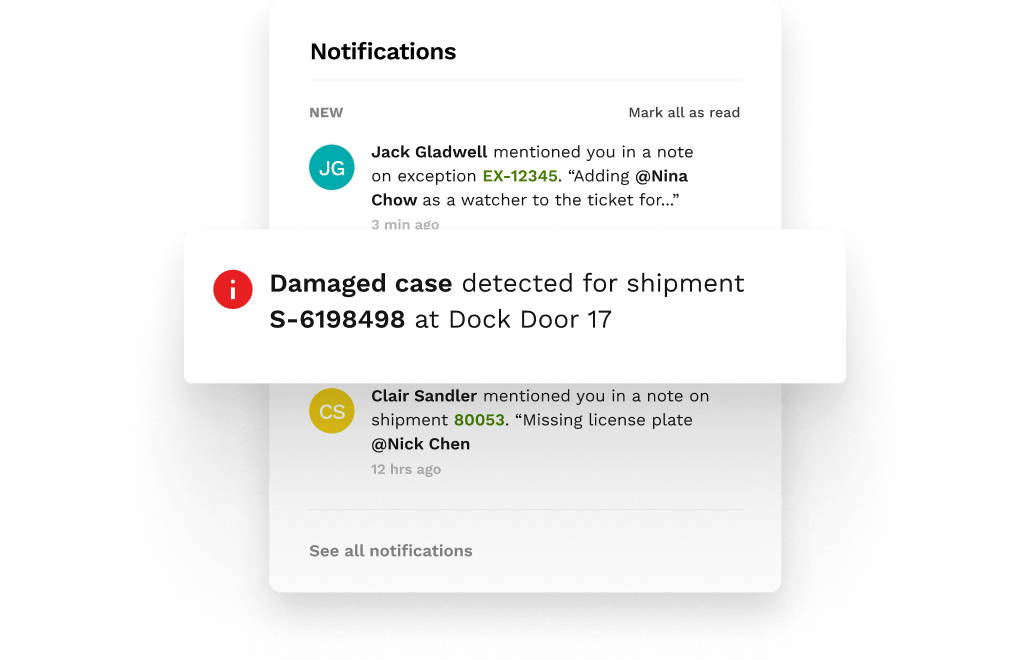

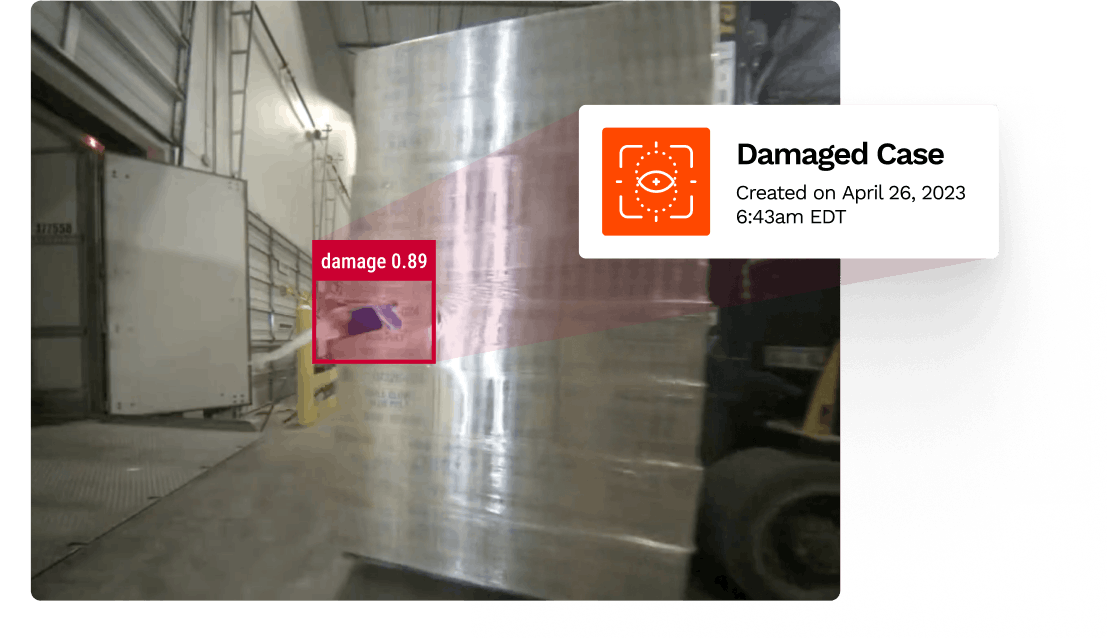

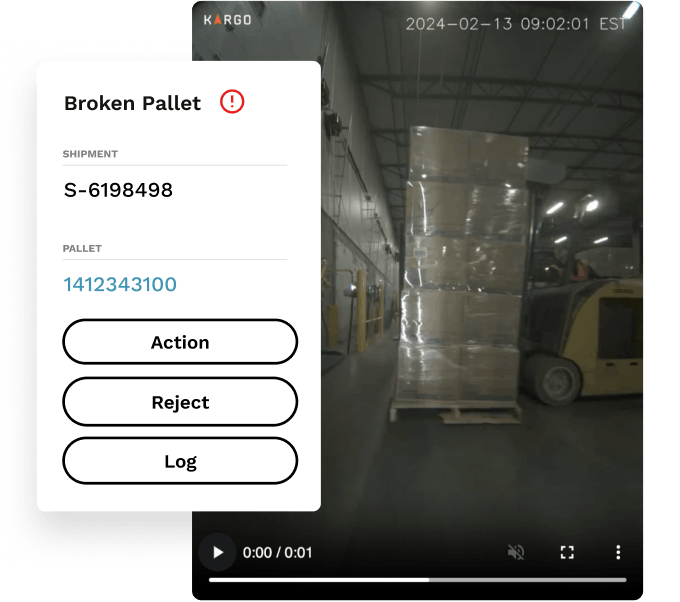

Detect Damage at the Door

Kargo detects and flags damage at the dock door so you can address issues before they escalate.

- Catch Inbound Issues: Get notified about damaged freight in real-time to avoid operational delays and financial repercussions.

- Assure Quality: Stop shipping damaged products and maintain good relationships with partners.

- Get Visual Proof: Easily access irrefutable video evidence of damage on the Kargo Platform, simplifying claims processes.

The Breakdown

Using computer vision, Kargo detects and identifies damaged product and pallets as it passes through the dock door

Kargo instantly notifies the forklift driver and supervisor, so they can address it immediately

902mis-ships prevented by Kargo in one year

See how Armada was able to improve shipping and receiving accuracy and reduce inventory loss.

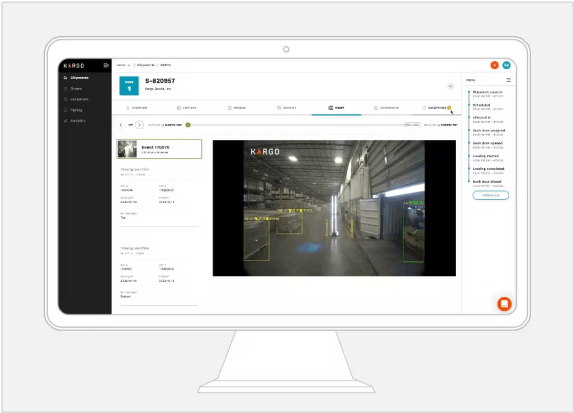

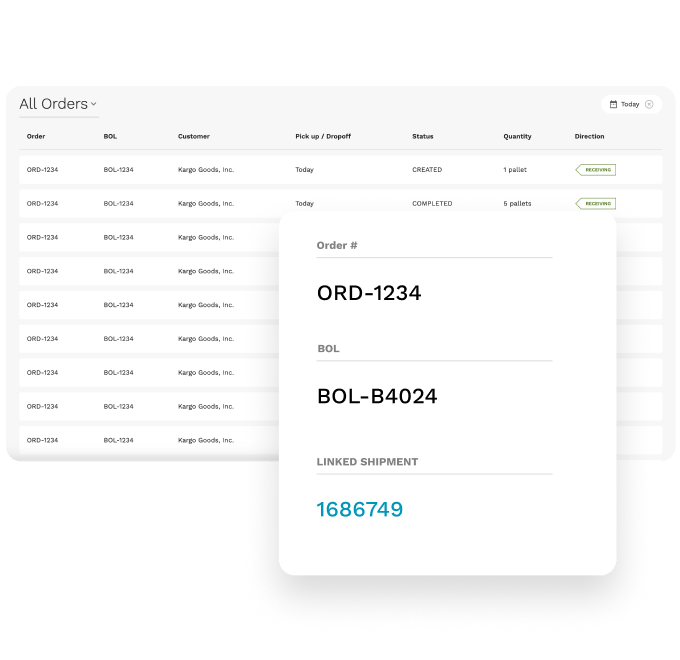

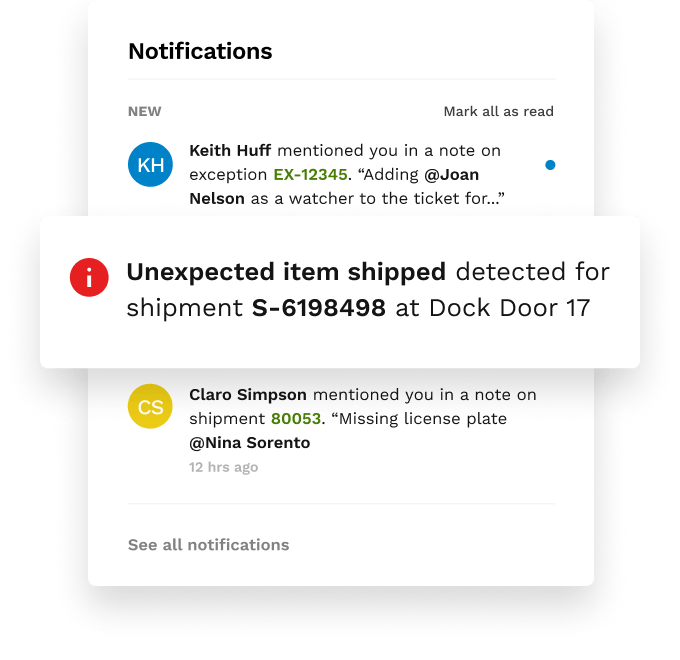

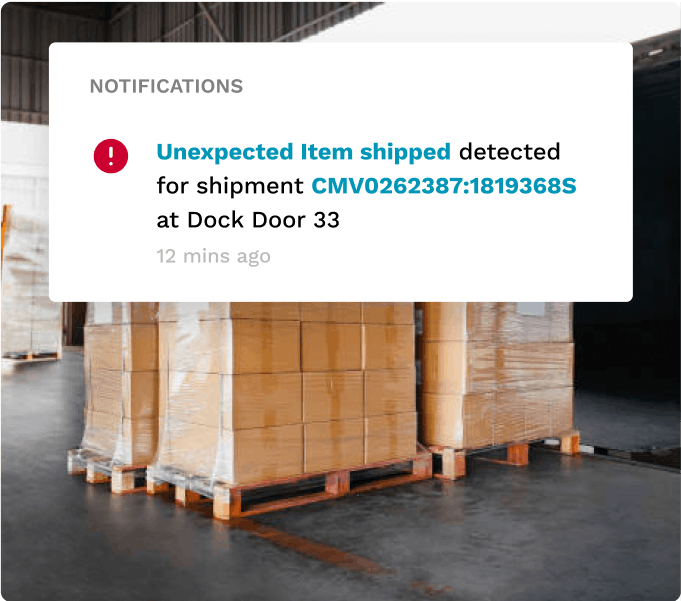

VERIFY SHIPMENTS WITH UNMATCHED ACCURACY

Kargo verifies the contents of every shipment, flagging discrepancies to eliminate costly mistakes.

- Prevent Mis-Ships: Catch and correct issues with outbound shipments before the truck leaves, avoiding claims, inventory loss and more.

- Catch Inbound Errors: Identify and record discrepancies before they enter your inventory.

- Ensure Compliance: Maintain customer and industry standards by catching expired product, incorrect labeling and documentation errors.

The Breakdown

Use your existing process to send orders to Kargo

As the trailer is loaded or unloaded, Kargo captures data from freight labels and compares the contents of the shipment against its orders

Kargo immediately notifies the forklift operator and supervisor of any discrepancies so they can address the issues

Implementing fluid loading has been a game-changer. By automating processes with Kargo, we’ve been able to handle higher volumes with greater accuracy, positioning us for sustained growth in a competitive market.”

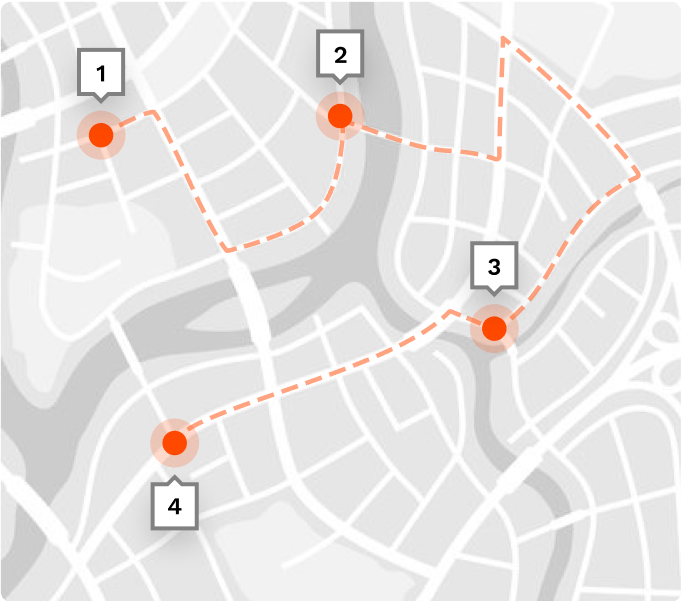

PERFECT LOAD SEQUENCING

Kargo ensures every order is loaded in the correct sequence, enhancing efficiency and customer satisfaction.

- Achieve Accuracy: Instantly identify and rectify mistakes including incorrect order, mixed loads, and special requirements.

- Lock-In Satisfaction: Deliver orders exactly as specified, every time.

- Boost Efficiency: Streamline your loading process for improved shipping and receiving.

The Breakdown

Receive the load sequence and input into the Kargo Platform

As the trailer is loaded, Kargo uses computer vision to catch deviations

Kargo notifies the forklift operator of any loading errors in real-time so they can fix them immediately

LEARN MORE

Ready to see how Kargo can optimize your operations? Tell us: